This website uses cookies for a better browsing experience.

If you agree to the use of cookies, please click the "Agree" button.

Please refer to the Privacy Policy regarding the use of cookies on this site.

To improve the seismic performance of a bridge as a whole, increase its long-term durability, and reduce construction costs

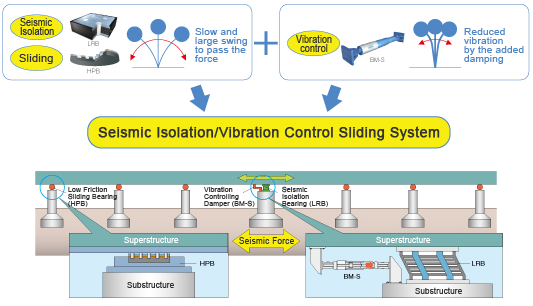

What is seismic isolation and vibration control sliding system?

- Definition

“A system that uses seismic isolation bearings and vibration dampers in the substructure of specific spans to control the behavior of a multi-span continuous girder bridge that is unlikely to collapse during an earthquake. Sliding bearings are installed between abutments to isolate the upper and lower structure. This seismic-resistant structure is less susceptible to statically indeterminate forces caused by temperature changes and other factors.

- Effects

- No need to adjust horizontal displacement during construction, e.g., post-sliding

- Reduces the effects of statically indeterminate forces due to temperature changes and other factors on the seismic performance of bridges

- Reduces seismic inertia with a longer period than that of the bridge

- Use of low-friction sliding bearings in footings enables slimming down of footing columns and foundation piles

- Seismic isolation bearings and vibration dampers can provide significant damping performance

How the seismic isolation and vibration control sliding system works

A seismic isolation and vibration control sliding system provides a combination of seismic isolation, sliding, and vibration control in a single bridge.

Structure and characteristics of Oiles HPBs

- Suitable for a high surface pressure and high speeds

The Oiles HPB uses a low-friction sliding material that can handle a high surface pressure and high speeds using technology related to bearings, which are our core products.